So, you want to electrify your fleet. That’s a smart move. But if you’re feeling stuck, you’re not alone. Many companies find their fleet electrification planning hits a wall. The reason is simple, but almost everyone misses it.

They’re following the wrong map.

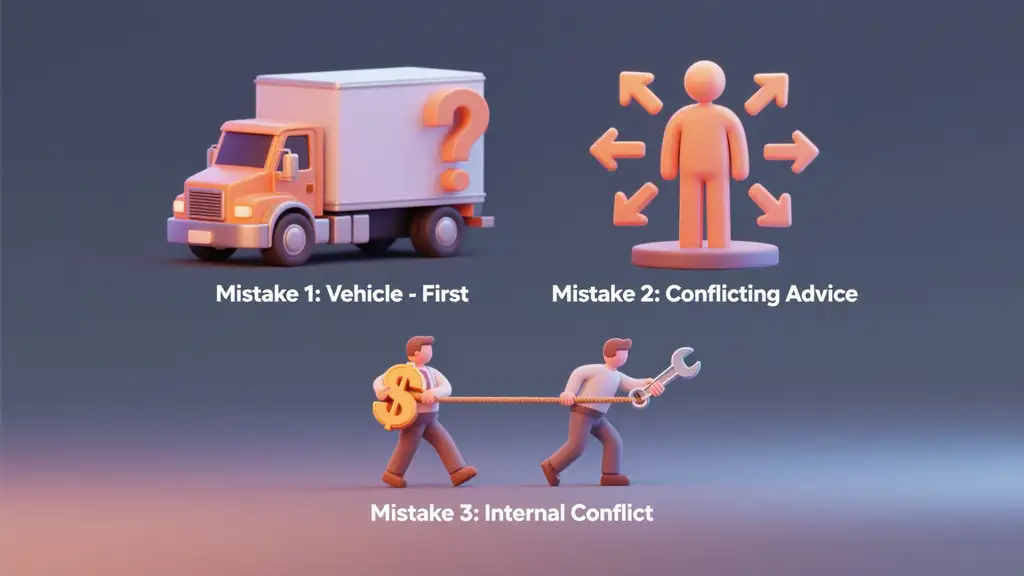

The first thing most people do is look at electric vehicle models. It seems logical. But it’s the biggest mistake you can make.

Focusing on the vehicle first is like building a house without checking if you have water or electricity. Your entire operation depends on energy. If you don’t have a solid, cost-effective charging plan, the fanciest electric truck is just a very expensive lawn ornament. A groundbreaking study from the Fraunhofer Institute proved that optimizing the charging plan before choosing vehicles can double the work done by electric trucks and nearly triple the cost savings.

The market is noisy. Consultants tell you to focus on high-level strategy. Software companies say data is everything. And hardware vendors just want to sell you chargers.

Everyone is selling their piece of the puzzle. But nobody is showing you how to put it all together. This leaves you confused and paralyzed, unable to make a confident decision.

Here’s the real secret. Your fleet electrification planning isn’t just stalling because of technical problems. It’s stalling because of people problems.

These two goals are in direct conflict. The CFO wants to spend less, while the fleet manager needs guaranteed performance. This internal tug-of-war is often the biggest barrier to moving forward, a problem that originates at the executive level, not with the fleet manager.

To succeed, you need to flip the script. Stop thinking about vehicles. Start thinking about energy. This is the revolutionary shift that turns a costly, complex project into a profitable, streamlined operation.

Think about it. An electric truck is just a device that uses electricity. The real magic—the place where you make or lose money—is in how you manage that electricity.

Your charging infrastructure, powered by smart software, is the “intelligent energy hub” of your entire fleet. It’s not just a plug on the wall. It’s the central nervous system that connects your vehicles, your drivers, your budget, and your sustainability goals.

Don’t just take our word for it. The data is clear.

The Fraunhofer Institute ran a detailed study comparing two strategies :

The results were stunning. The “Smart Replanning” approach more than doubled the amount of work done by electric trucks (from 26% to 55% of ton-kilometers) and delivered nearly three times the Total Cost of Ownership (TCO) savings (up to 8% vs. just 3%). This proves that how you charge is more important than what you drive.

A smart charging strategy isn’t a cost center. It’s the key to unlocking value for everyone in your company:

To get your CFO on board, you need to speak their language: Total Cost of Ownership (TCO). But most TCO calculations are dangerously incomplete. They focus on the sticker price of the truck and miss the most important variable.

The upfront cost of an EV is high. We get it. But that’s a known, one-time expense. The real financial risk—and the biggest opportunity for savings—is in your ongoing energy costs.

This isn’t just about the price per kilowatt-hour. It’s about a hidden cost that can destroy your budget if you’re not careful.

Demand charges are extra fees your utility company charges based on your highest peak electricity usage in a month, not just how much you use overall.

Imagine this: you plug in 10 trucks to fast-charge at the same time when they return to the depot. This creates a huge spike in electricity demand. Even if it only lasts for 15 minutes, that single spike can set a high “demand charge” that you pay for the entire month. It can easily add thousands of dollars to your bill and wipe out any fuel savings you thought you had.

A true TCO analysis for fleet electrification planning goes way beyond the basics. Use this comprehensive table to build a real-world financial case.

| Cost Category | Components | Key Considerations for EVs |

|---|---|---|

| Upfront Capital Costs | Vehicle Purchase Price | Higher initial cost, but incentives can close the gap. |

| Federal/State/Utility Incentives | Crucial for reducing net cost. Can cover vehicles AND infrastructure. | |

| Infrastructure (The Big One) | Site prep, utility upgrades, transformers, trenching, and permits. | |

| EVSE Hardware (Chargers) | Cost varies by power (Level 2 vs. DC Fast) and features. | |

| Installation & Commissioning | Requires certified electricians and can be a significant cost. | |

| Management Software | Subscription fee (SaaS), but essential for controlling operational costs. | |

| Ongoing Operational Costs | Energy (The Variable) | This is your biggest lever. Includes per-kWh rates, demand charges, and time-of-use rates. Highly optimizable with software. |

| Maintenance & Repairs | Significantly lower for EVs (up to 50-75% less). No oil changes, fewer moving parts. But technician training is a new cost. | |

| Insurance | Can be higher for EVs due to higher vehicle value and repair costs. | |

| Driver Training | Needed for regenerative braking and efficient driving techniques. | |

| End-of-Life Costs | Depreciation / Residual Value | Historically uncertain, but improving. Battery health is the key factor. |

| Battery Replacement / Second Life | A potential major expense ($15,000+), but batteries may have resale value for energy storage. |

Ready to build a plan that actually works? Forget the old way. Follow this energy-first approach for your fleet electrification planning.

Before you even look at a single EV model, look at your facility and your utility bill.

Now, design the brain of your operation. This is the most critical part of your fleet electrification planning.

Now, and only now, do you start looking at vehicles. With your energy strategy in place, your choices become much clearer.

This is where the plan becomes reality.

Your fleet electrification planning doesn’t stop at deployment.

You have a solid, energy-first plan. Now you need to get buy-in from the key decision-makers. You need to show each of them how this plan solves their specific problem.

The path to a successful, profitable electric fleet is clear. It requires a fundamental shift in thinking. Stop seeing fleet electrification planning as a vehicle procurement project. Start seeing it as an energy management strategy.

The companies that win will be the ones who understand that the charger and its software are not an afterthought; they are the heart of the entire system. They are the engine that drives operational efficiency, financial savings, and sustainable growth.

Don’t let your transition stall because you’re following an outdated map. Take control of your energy, and you will take control of your future.

Ready to build an energy-first plan that delivers real ROI?

Contact us today for a personalized fleet charging potential assessment. We’ll help you analyze your fleet’s unique needs and build a custom blueprint for a profitable electric future.

Sources & Further Reading

Fraunhofer Institute for Systems and Innovation Research ISI: “Optimizing the Electrification of Heavy-Duty Truck Fleets”

Geotab Marketplace: “Fleet Electrification Planning Tool”

ICF Consulting: “Fleet Electrification Advisory and Consulting”

Automotive Fleet: “Calculating a True TCO for EVs”

U.S. Department of Energy: “Hybrid Electric Vehicle Fleet Cost Calculator Tool”

Blink Charging: “Fleet EV Charging Solutions”

SupplyChainDive: “Key considerations for fleet electrification success”

Fleet EV News: “Why the fleet manager’s boss is the biggest barrier to EV transition”

Terawatt Infrastructure: “How to Better Predict your EV Fleet’s Total Cost of Ownership”

Enterprise Fleet Management: “EV Case Study with Geotab”

Environmental Defense Fund (EDF): “Electric Fleet Stories”

California Department of General Services (DGS): “State Fleets Case Study”

RTA Fleet Management: “Top Challenges Facing Fleet Managers in 2025”

AZOWO: “The Fleet Manager’s Transition Plan to Electric Fleets”

Element Fleet Management: “Element Appoints Chief Legal and Sustainability Officer”

Enviar-lhe-emos informações técnicas detalhadas e um orçamento!