I. Scalability Revolution: Dynamic Power Architecture Aligned with Business Growth

1.1 Elastic Capacity Expansion Mechanism

- Modular Power Stacking: Supports linear scalability from 5 kW to 2 MW, with expansion downtime <15 minutes (vs. 4–6 hours for traditional solutions).

- Cross-Generation Compatibility: Voltage tolerance of ±10% allows hybrid use of modules across three technology generations.

- Case Study: A data center achieved 400% phased capacity expansion over three years using modular stacking, reducing total cost of ownership (TCO) by 32%.

1.2 Spatial Efficiency Optimization

- 3D Stacking Density: Power density per unit area reaches 2.3× that of traditional designs (validated per IEC 61439-2).

- Hot-Swap Compatibility: Reduces module replacement workspace requirements by 60%.

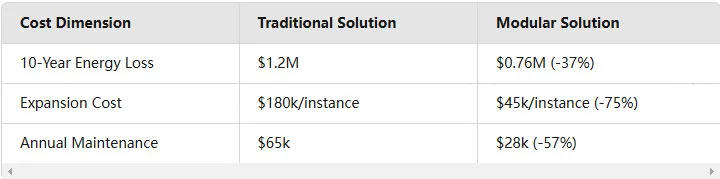

II. Lifecycle Cost Transformation: From CAPEX to OPEX Paradigm Shift

III. Reliability Leap: Intelligent Redundancy and Fault Isolation

3.1 N+M Redundancy Innovation

- Dynamic Load Balancing: Supports 0.5 ms fault module isolation during operation.

- Hybrid Redundancy Modes: Configurable N+1, 2N, or 3N redundancy levels, achieving 99.99995% system availability.

3.2 Multi-Dimensional Fault Tolerance

- Electrical Isolation Design: Limits arc energy of faulty modules to <1.2 cal/cm² (per NFPA 70E standards).

- Digital Twin Alerts: Predicts capacitor aging and other failures 48 hours in advance.

IV. Accelerated Technology Iteration: Future-Proof Upgradability

4.1 Hardware Evolvability

- Hybrid Topology Support: Compatible with LLC, PSFB, and DAB converter architectures in a single rack.

- SiC-Ready Design: 1700V voltage margin reserved for next-gen wide-bandgap devices.

4.2 Software-Defined Capabilities

- Open API Architecture: Integrates deeply with BMS/EMS systems, offering 200+ configurable parameters.

- Remote Firmware Updates: Secure OTA updates ensure a 20-year technology lifecycle.

V. Green Efficiency Breakthrough: Synergy Between Performance and Sustainability

5.1 Dynamic Efficiency Optimization

- AI Tuning Algorithms: Real-time load tracking flattens efficiency curves to ±0.8% variation.

- Multi-Mode Switching: Intelligently shifts between CCM/DCM/QR modes, boosting light-load efficiency by 9%.

5.2 Circular Material Economy

- Modular Disassembly Design: Enables 95% material recycling (ISO 14040 certified).

- Carbon Footprint Tracking: Each module includes a digital passport for lifecycle emissions.

Our Core Strengths: Modular Expertise Empowering EV Charging Infrastructure

As a TÜV SÜD-certified EV charging equipment manufacturer, we integrate modular power stack philosophy into product development:

1. Full-Scenario Validation System

- 50+ module configurations spanning 7kW–600kW power ranges.

- Extreme environment testing: Efficiency fluctuation <1.5% across -40°C to +85°C.

2. Smart O&M Ecosystem

- Cloud-based health management monitors 5,000+ modules simultaneously.

- 99.3% accuracy in fault self-diagnosis.

3. Customer Value Delivery

- Global module replacement response time <4 hours (85% coverage).

- End-to-end EMC compliance from prototyping to mass production.

Our engineering team offers:

✅ Free Modular Retrofit Feasibility Report

✅ TCO Comparison: Existing vs. Modular Systems

✅ Custom Redundancy Solutions (N+1 to 3N)